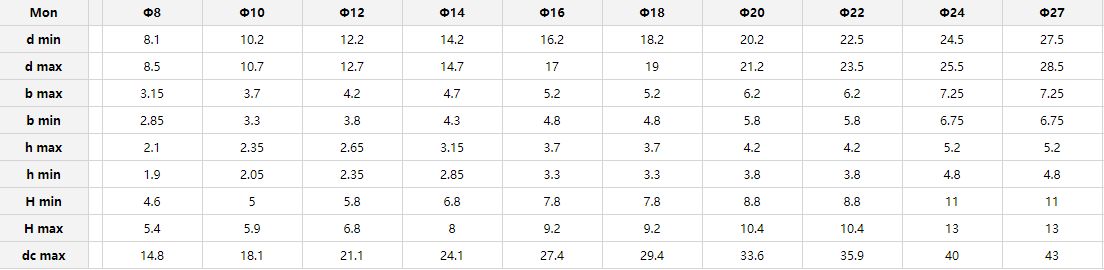

Specifications: M6-M48

Standard: DIN standard

Material: Low Carbon Steel, Middle Carbon Steel

Finish: Zinc plated, ZP,HDG

Delivery: 30-60 days

Keywords: spring washers, DIN7990 DIN127, bolts nuts washers spring washers ,flat washer spring washers DIN127, hex nuts washers lock spring washers, gasket

Main purpose of spring washers

The spring washer device is under the nut to prevent the nut from loosening.

It is stated in national standards.

The hexagon slotted nut is specially used with the bolt with hole at the end of the screw to insert the cotter pin into the hole of the screw from the slot of the nut to prevent the nut from loosening automatically. It is mainly used for occasions with vibration load or alternating load.

The methods to prevent automatic loosening of nuts (or bolts) in mechanical design and manufacturing are as follows:

1. Add spring washer; (Easy to do)

2. Use hexagon slotted nut+cotter pin; (Processing procedures were added on a year-on-year basis)

3. Add washer; (Processing procedures were added on a year-on-year basis)

4. The hexagon head opening of the hexagon bolt is inserted into the steel wire. (Processing procedures were added on a year-on-year basis)

The spring washer is used to prevent looseness. For example, the bolt connecting the motor and the base should be added with a spring washer generally, because if the motor vibrates without a spring washer, the nut will loosen. Generally, the fastener on the equipment with vibration is equipped with a spring washer, and the flange does not need to be added with a washer generally! The addition of spring washer on the flange is related to the medium flowing through the pipeline. If it is easy to generate pulse, it is better to add spring washer, as well as high-speed fluid, and the caliber changes frequently. Don't generalize. Some valves require spring washer on the stuffing box gland flange The quick, easy and optimal automatic selection of spring washer is included.